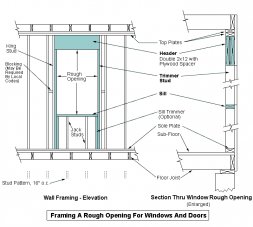

This article was written as a companion to Installing A New Window In An Old Wall, but the discussion also applies to new construction framing. This article assumes that the reader has a basic familiarity with the components of standard platform framing, such as studs, headers, joists, etc.

During the first couple of centuries after Europeans settled in North America a common method of house framing used large timbers for the main structural supports. This is called post-and-beam framing and it fell out of favor in the 1800's, perhaps because large timbers increased in cost as forests were depleted, or because houses framed with lighter pieces of wood offered similar qualities for a lower cost and were easier to produce in large numbers.

The vast majority of houses in the United States and Canada have walls that are built from an array of vertical supporting columns called studs. These supports are placed quite close together, typically spaced 16" from center-to-center, but sometimes spaced at 24". This tight spacing makes it easy to apply sheet materials (such as plywood or drywall) and strip materials (such as siding boards or lath for plaster) on the inside and outside.

But the close stud spacing has a drawback: only very narrow windows or doors could be installed, unless some studs are omitted (creating a weak area) or some special method is devised to transfer the overhead loads (the weight of the roof or floor above) to studs on each side of the opening.

Carpenters use some simple framing techniques to achieve this transferring of loads. It involves a sturdy beam called a header, made from multiple pieces of dimension lumber. The ends of this beam rest on a short stud which is fastened to a full-length stud. The following pictures tell the story better.

Using Headers That Are Just Big Enough

The blue shaded areas in the drawing below highlight some of the main components used in the framing of a typical window opening when a header is used that does not reside against the top plate.

This method is used for a number of reasons:

- To save on material cost. 2x12's are expensive, and the benefit from using them comes mainly from the simplicity and lack of cutting needed for the small cripple studs. For do-it-yourselfers, this method makes sense because labor costs are not much of an issue.

- When the house has ceilings higher than than 8 feet, which is becoming increasingly common.

Figure 1: Using 2x6's, 2x8's, etc. For Header Framing

Note how the king studs and trimmers are not necessarily on the same pattern as the regular 16" spacing of the wall studs. Often the building plans require that the window be placed in the center of a wall and it just happens that the king/trimmer studs fall in between two regular studs. If the king/trimmer are close to the stud pattern (within 1 or 2 inches), I will often place them on the pattern and then fill in the opening with scraps of 2x4's to make the desired rough opening.

Also note the blocking between the king stud and the next stud. Supposedly, some local building codes require this, though I haven't seen any carpenters do this extra step in my area. But my experience tells me that these small blocks of wood make a significant improvement in the stiffness of the king/trimmer studs, especially if plywood or OSB sheathing is not used. My engineering background tells me that improving the stiffness of a vertical support can make a difference in its strength, because when columns and posts fail, they often fail by buckling. These small blocks take only a few minutes to install and can help prevent buckling failure.

Header Sizing:

This table was found in a book titled Fundamentals Of Carpentry - Practical Construction, (5th Edition), by Walter E. Durban and Elmer W. Sundberg, published in 1977 by American Technical Society. Page 178.

Header Size: |

Application: (Distance Spanned) |

| 4x4 inch | Up to 4' |

| 4x6 inch | 4' to 6' |

| 4x8 inch | 6' to 8' |

These dimensions apply to headers in one story buildings with normal roof loads (i.e. not in a snow belt or exposed to unusual winds such as in coastal areas).

Note that the header sizes are nominal, so a 4x4 inch header could have actual dimensions of 3-1/2" by 3-1/2". Solid headers or built-up headers (made from double 2x boards on edge, with a spacer) can be used. Today there are many options with headers, such as laminated veneer lumber (LVL) and other glue/wood composite beams classified as "engineered lumber" that offer strength and stiffness superior to ordinary dimension lumber.

In some cases these header sizes may not be accurate. Contact your local Building Department or Building Code Official for the most accurate information pertaining to your project.

Going Overboard: Using 2x12's For All Headers

Similarly, the blue areas in the drawing below highlight some of the main components used in the framing of a window opening when a 2x12 header is used and placed up against the top plate. I'm also trying to show an alternate method of framing the sill, a method that I sometimes use.

Note how the trimmer studs go from the floor to the header with no breaks, and a pair of short "Sill Trimmers" (a name I just made up) support the horizontal sill. I believe this is a stronger method of framing a window opening because the trimmer studs that support the header are complete.

This method is essentially the same as framing a door opening and filling in the lower area with jack studs and a sill that runs between two trimmer studs. Of course, for a door opening the bottom plate is cut out after the wall sections are tilted into place.

Figure 2: Using Double 2x12's For Header Framing

With the usual method (the lower part in Figure 1), the sill bears the weight of the trimmer studs, which is not a problem until the structure ages for a few decades and two things happen. One, the sill shrinks and no longer fits tightly, so it offers no support for the trimmer. And two, the nails that hold the trimmer and the king stud together loosen over time. I've done a fair amount of work on old houses and I'm always astonished at the looseness of many of the nails. This is an inevitable event that is caused, I believe, by the drying of the wood, rusting of the nails, and the racking (flexing) of the structure in the wind.

There are some other benefits to using this "full trimmer" method:

- If the window is ever replaced with a door, the framing work will be straightforward. True, the 2-piece trimmer method works okay, but the sill has to be cut, and the result is a tiny block of wood to support the upper section of the trimmer. If the nails stayed tight, this would not be a problem. I would recommend the full trimmer method of window framing if changes such as an addition to the structure are planned. Then the window can be easily replace with a doorway, providing there is no wiring below the window.

- If you aren't 100% certain of the window size when doing the framing. With this method the sill can be modified easier, accommodating a taller window.

With very wide window openings (6 feet or more), I would only use the full trimmer method, because the load on the trimmers can be quite high and I would not take any chances. The extra expense of this method is worth it, and some building codes may require it. For small 2 foot wide windows the benefits are minimal.

Some drawbacks are:

- Added cost of material and labor.

- It can be more difficult for an electrician to drill holes through the triple studs. It could be impossible to see some nails, thus damaging a drill bit.

by old do you mean used or antique style frame?

If you want used stuff flea market, thrift store and craigslist are great place to start. Make sure you measure the size before you go out and buy one